- Coating and laminating calenders

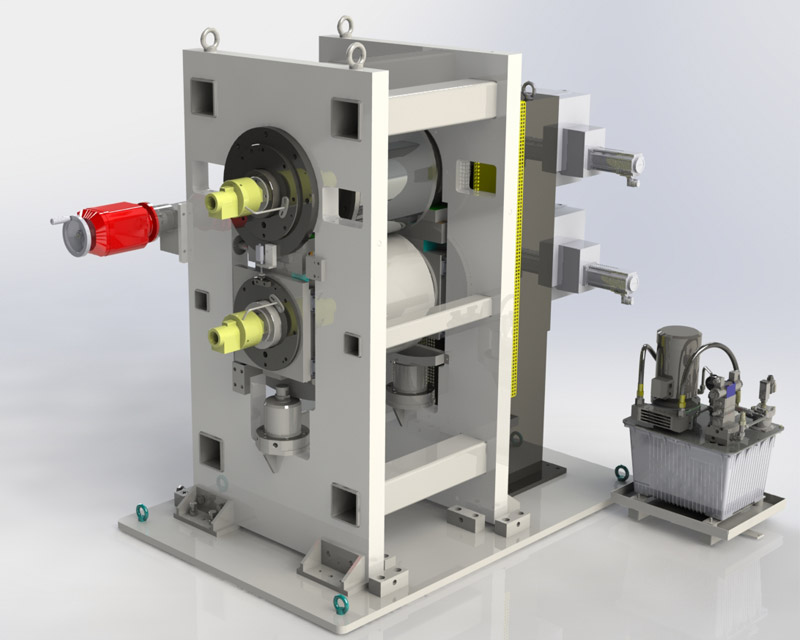

- Calibrating calendars

Machines with this technology are increasingly becoming the focus of state-of-the-art finishing processes where the same or different materials must be connected to each other in a positive manner in order to create a new quality. Demanding lamination processes require precision technical solutions where matched pairs … read more of driven precision rolls, heated or cooled, form the core part of the machine. A solid, well-developed design and the ability to reproduce technological processes satisfy the high standard that our calenders fulfil.

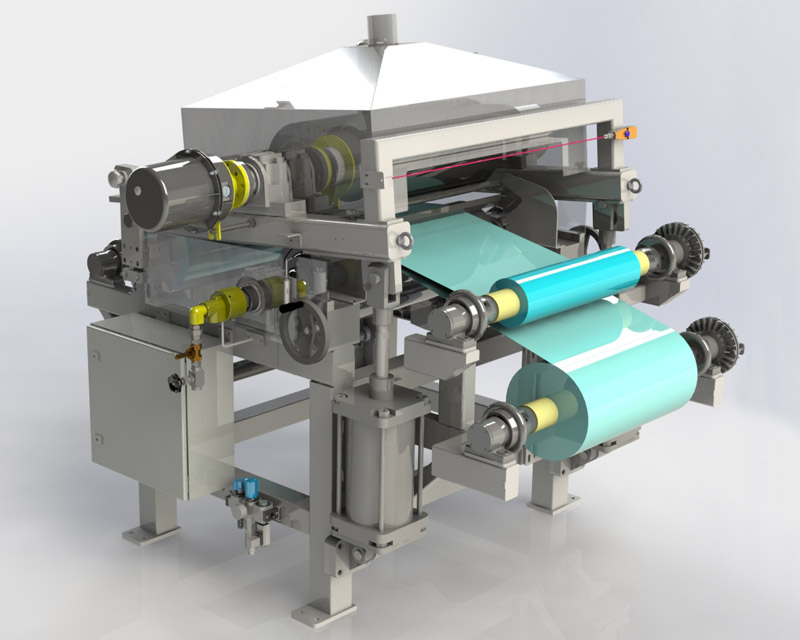

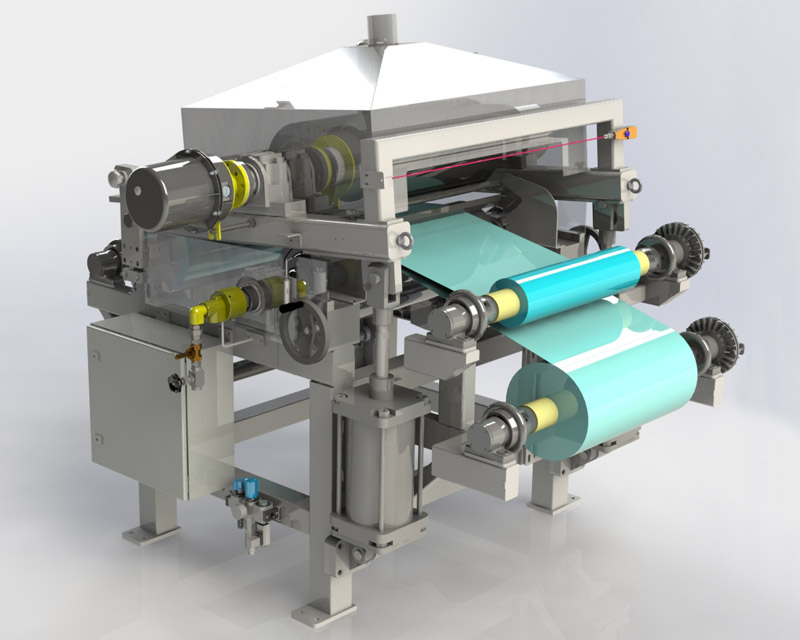

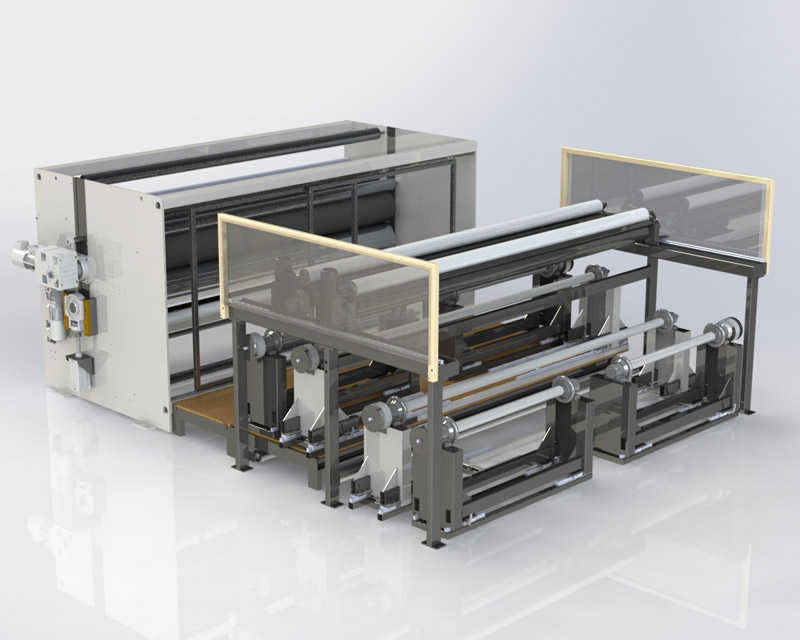

Coating and laminating calenders

- Working widths up to 6,000 mm

- Cooled or heated rolls

- High temperature version to 500 °C

- Electrical gap adjustment

- Sag compensation

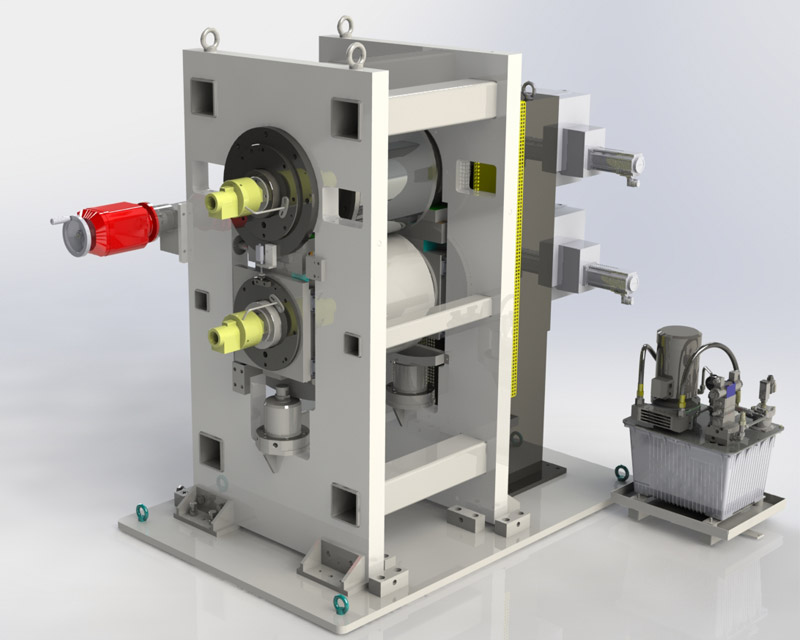

Embossing, smoothing and compressing different materials with high, uniform contact pressure and precise temperature stability with exact concentricity of the calibrating rolls constitute the outstanding characteristics of our calibrators. Depending on the requirements, it is possible to use heated … read more or cooled, smooth or structured precision rolls for this. Pre-assembly and advance commissioning assure fast, smooth handover and satisfied customers.

Calibrating calendar

- Working widths up to 6,000 mm

- Sag compensation

- Hardened rolls

- Heating or cooling/li>

- High-precision gap adjustment

- Hydraulic contact pressing