- Winders

- Material accumulators

- Special systems

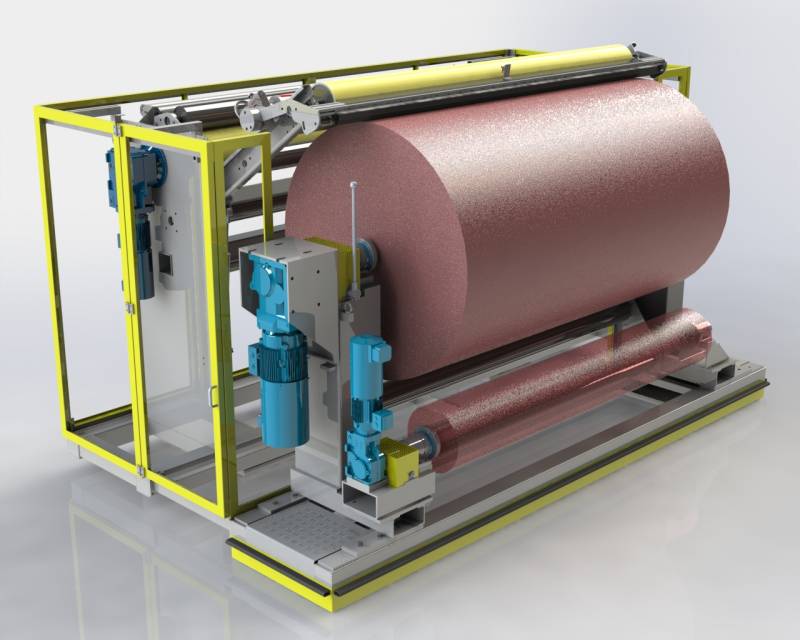

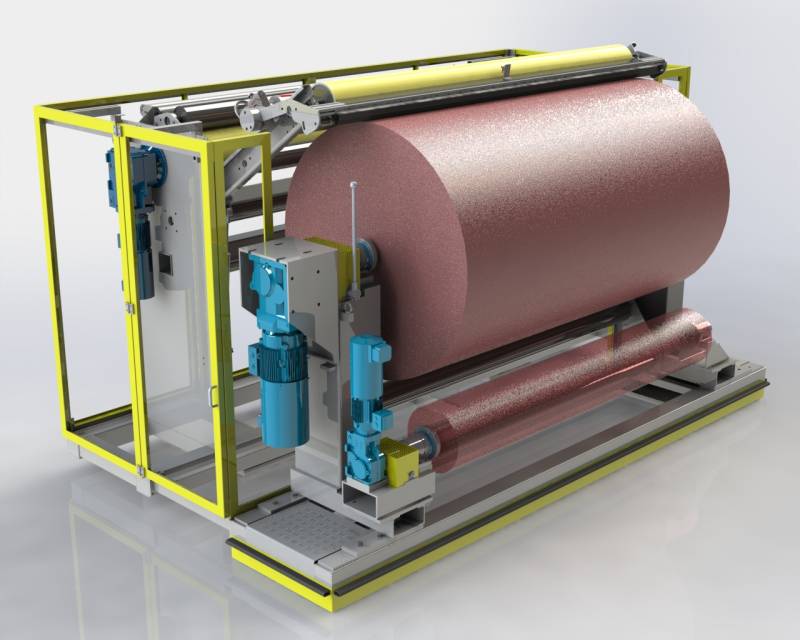

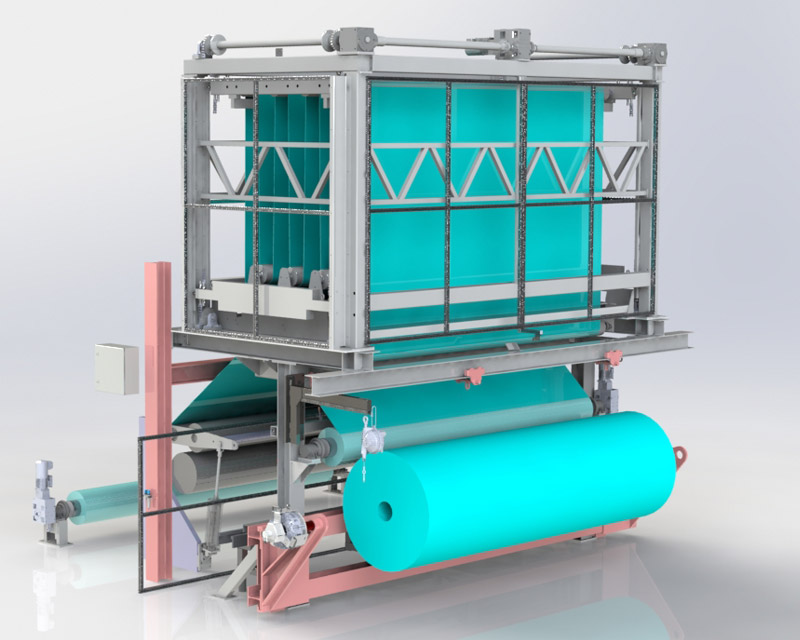

Unwinding and winding systems are essential in the textile branch and similar industries. The requirement profile is both special and complex. If the application calls for customer-oriented individual solutions, we offer the latest, precisely matched winding units that can be designed to be both fixed and movable. … read more State-of-the-art drive technology, reliability, accuracy and reproducibility are the fundamental preconditions of our winding technology. A wide range of different winder versions is available, including ascending batch winders, centre winders, surface winders, dye beam winders, combination winders or automatic winders.

Winders and unwinders

- Centre and surface drive

- Semi-automatic winding

- For flexible and solid materials

- Freely-programmable characteristics

- Reproducible fabric tension

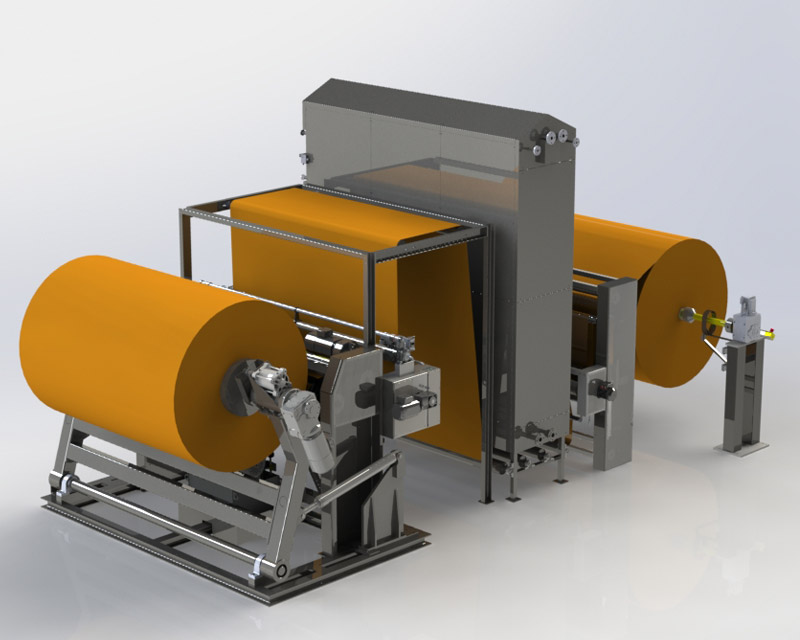

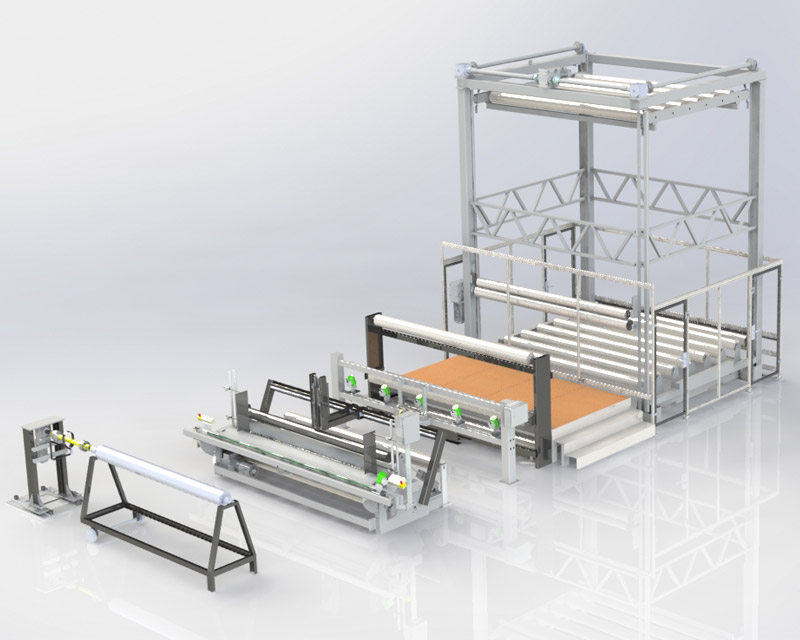

For the equipping process to run smoothly and to avoid system stoppages that have several negative effects up and including greater costs, the use of accumulators is often essential. These range from the simplest form to sophisticated roll or comb accumulators with correspondingly high storage volumes. A PLC ensures a … read more problem-free fabric run, i.e. storage and subsequent clearing in the right amount and at the specified time.

Material accumulators

- Roll widths up to 6,000 mm

- Electrical roller mill adjustment

- Continuous fabric tension control

- With and without pulling unit

- Fabric feed from underneath

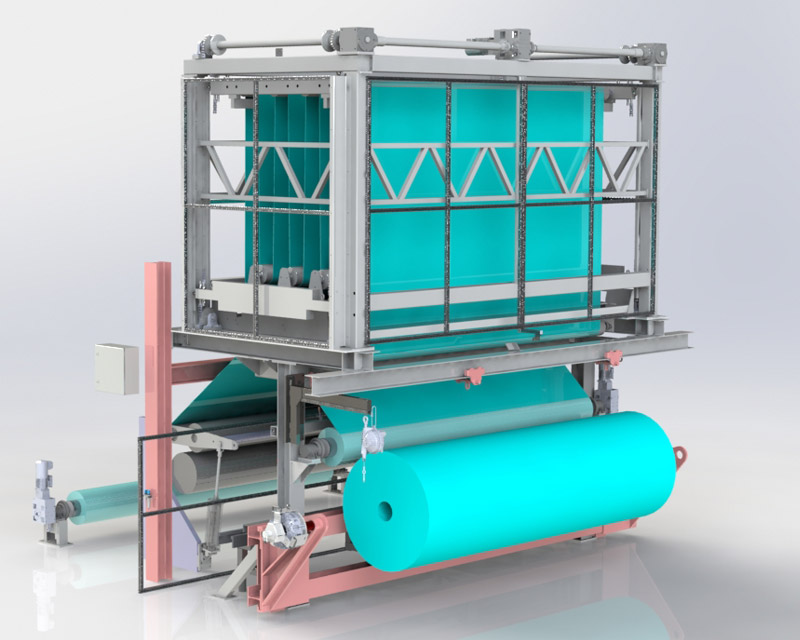

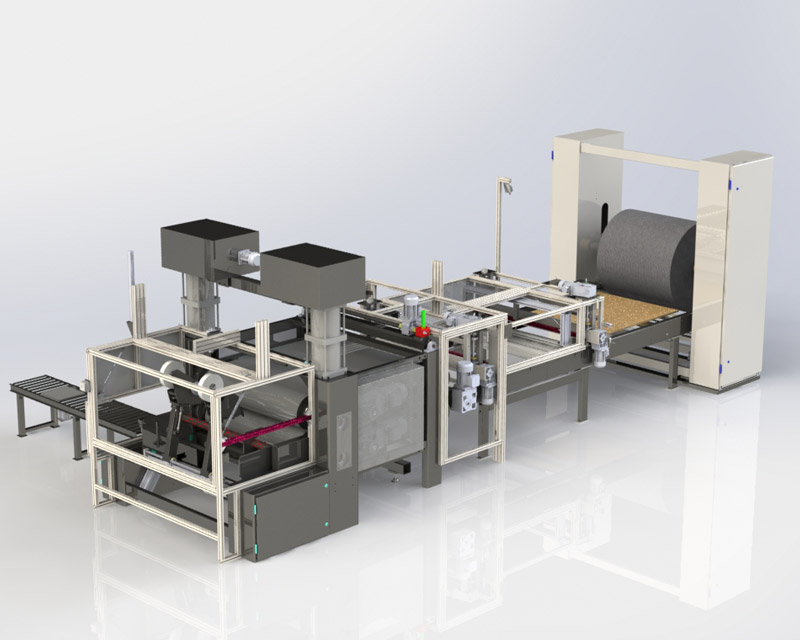

The main demand today in our textile machine engineering is for special solutions, depending on the innovative market conditions. These cannot be put into any pattern or classified in any repeatable, serial machine construction. Our team is set up to manufacture special systems or customised machines that are integrated … read more in current textile or textile-like processes. These system components and special systems are also used in applications as special drying units, accumulators, special winders and plaiters in tubular fabric dewatering as well as in special fabric inspection systems.

Special systems

- Working widths up to 6,000 mm

- Made to customer-specific requirements

- Project planning in line with special standards (e.g. UL, FDA, ATEX )

- Installation and commissioning by our own personnel